Carbide, known for its hardness and durability, has become a preferred material in various industries, especially in cutting tools, drilling, and manufacturing applications. Composed primarily of tungsten carbide and cobalt, this composite material offers outstanding performance in demanding environments. However, despite its numerous advantages, carbide has several disadvantages that cannot be ignored. This article explores these drawbacks in detail to provide a balanced perspective on the use of carbide in industrial applications.

1. Brittleness

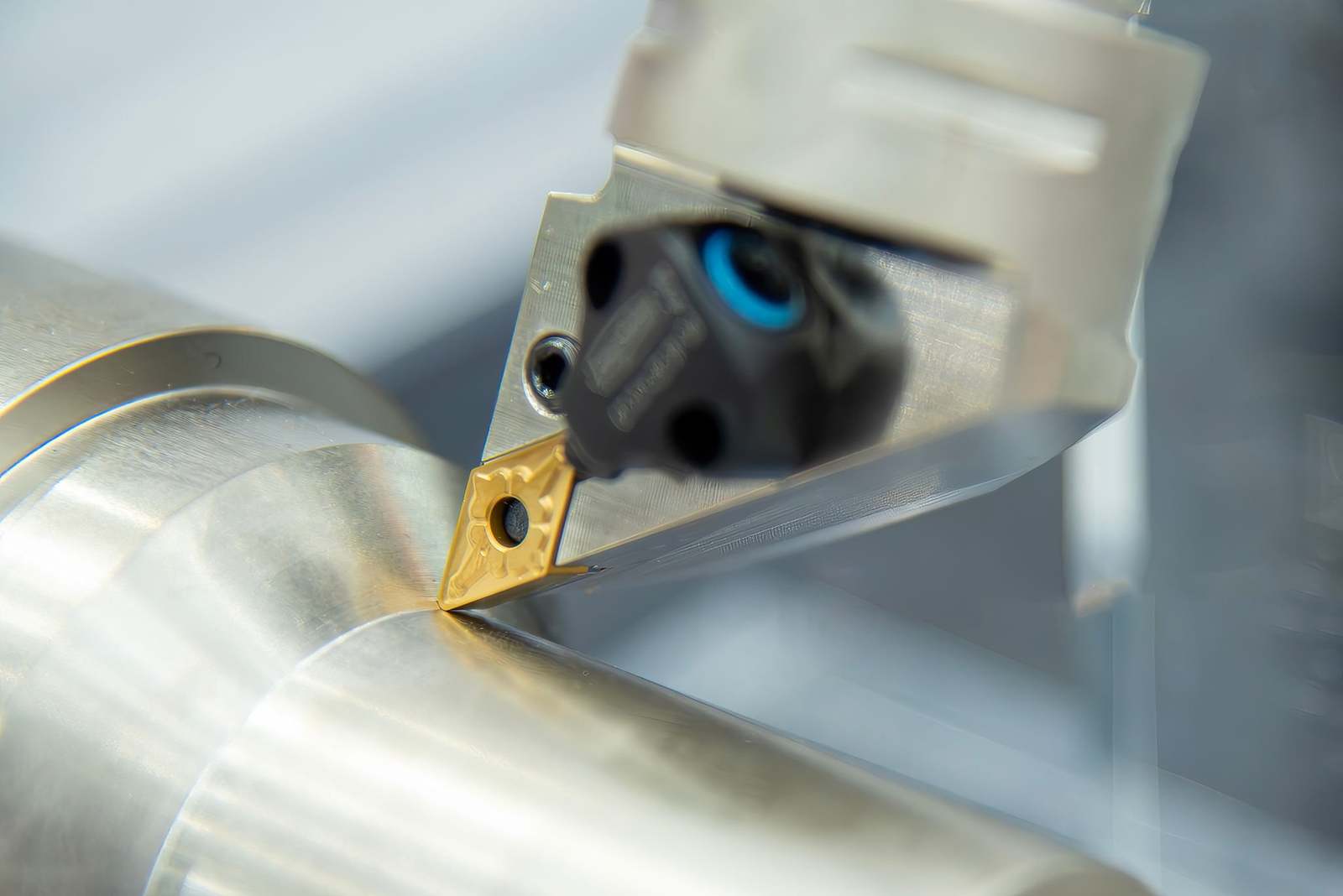

One of the primary disadvantages of carbide is its brittleness. Unlike materials such as steel, which can absorb impacts and resist deformation, carbide is prone to cracking or breaking under high stress or sudden impact. This brittleness limits its application in environments where tools or components are subjected to heavy shocks or vibrations.

For example, carbide cutting tools can easily fracture if they encounter a sudden change in the material being machined, such as a hard inclusion or an uneven surface. This property also necessitates careful handling during storage, transportation, and use, adding to operational challenges.

2. High Cost

Carbide is significantly more expensive than other materials like high-speed steel (HSS) or ceramic. The cost of raw tungsten carbide powder, combined with the complex processes required for sintering and shaping, contributes to its high price. Additionally, cobalt, which is used as a binder in carbide production, is a scarce and costly material, further driving up expenses.

This high cost makes carbide unsuitable for applications where affordability is a critical factor. For small-scale operations or low-budget projects, investing in carbide tools or components may not be economically viable.

3. Limited Resistance to Thermal Shock

Carbide has a high melting point and excellent thermal conductivity, but it performs poorly under rapid temperature changes. Thermal shock, which occurs when the material experiences sudden cooling or heating, can cause carbide to crack or lose its structural integrity.

In machining operations, this is particularly problematic. Tools made of carbide may fail prematurely when subjected to interrupted cutting or improper coolant application. This limitation necessitates strict process controls to maintain consistent temperature conditions during use.

4. Environmental Concerns

The production and disposal of carbide pose environmental challenges. The mining and refining of tungsten and cobalt, the primary constituents of carbide, have significant ecological impacts. These processes often involve hazardous chemicals and generate large amounts of waste, contributing to soil and water pollution.

Moreover, recycling carbide is a complex and energy-intensive process. While recycling can reduce the environmental impact, the infrastructure for carbide recycling is not as widespread as that for other materials. As a result, a considerable amount of used carbide ends up in landfills, where it may persist for years without decomposing.

5. Health Risks

The production and machining of carbide materials can pose health risks to workers. Tungsten carbide dust, generated during grinding or cutting, can be harmful if inhaled over prolonged periods. Similarly, cobalt, used as a binder in carbide, is classified as a potential carcinogen. Chronic exposure to cobalt dust can lead to respiratory problems and other health issues, such as cobalt poisoning or hypersensitivity pneumonitis.

To mitigate these risks, strict safety protocols and protective equipment are required in workplaces that handle carbide. However, implementing such measures increases operational costs and complexity.

6. Difficulty in Machining and Sharpening

Carbide's exceptional hardness makes it challenging to machine or sharpen. Specialized equipment, such as diamond-coated grinding wheels, is required to shape or resurface carbide tools. These tools and processes are costly and time-consuming, making maintenance and customization of carbide components more difficult compared to softer materials.

Additionally, the precision required in machining carbide increases the likelihood of errors and material wastage, further contributing to its disadvantages.

7. Weight

Carbide is denser than many alternative materials, such as aluminum or steel. While this density contributes to its strength and durability, it also makes carbide components heavier. In applications where weight reduction is critical, such as in aerospace or portable tools, this characteristic can be a significant drawback.

The weight of carbide tools can also lead to increased wear on machinery, higher energy consumption during operation, and greater strain on workers who handle them manually.

8. Corrosion Resistance Limitations

Although carbide is highly resistant to wear and abrasion, its resistance to corrosion is not as robust. In environments with high humidity, acidic conditions, or exposure to certain chemicals, carbide can degrade over time. Cobalt binder, in particular, is susceptible to chemical attack, leading to pitting and weakening of the carbide material.

Protective coatings can be applied to improve corrosion resistance, but these add to the cost and complexity of production.

9. Dependence on Limited Resources

The primary materials used in carbide production, tungsten and cobalt, are finite resources. Tungsten is classified as a critical raw material by the European Union due to its economic importance and supply risk. Similarly, cobalt is sourced predominantly from a few countries, with geopolitical and ethical concerns surrounding its mining practices.

This dependence on limited and geographically concentrated resources creates supply chain vulnerabilities. Price volatility and potential shortages of these materials can disrupt production and increase costs for industries relying on carbide.

10. Alternatives with Comparable Performance

In some applications, alternative materials such as ceramics, high-speed steel, or polycrystalline diamond (PCD) can offer comparable performance at a lower cost or with fewer drawbacks. These alternatives often provide better resistance to thermal shock, improved machinability, or lighter weight, making them preferable in specific scenarios.

The availability of these alternatives challenges the widespread adoption of carbide, particularly in industries where the benefits of carbide do not justify its higher cost and operational limitations.

Conclusion

While carbide is an indispensable material in many industrial applications due to its exceptional hardness, wear resistance, and thermal conductivity, its disadvantages cannot be overlooked. Issues such as brittleness, high cost, environmental impact, and health risks highlight the need for careful consideration when selecting materials for specific uses.

Understanding these drawbacks allows industries to make informed decisions and implement strategies to mitigate the limitations of carbide. Whether through improved recycling practices, enhanced safety measures, or the adoption of alternative materials, addressing these disadvantages is crucial for the sustainable and effective use of carbide in the future.