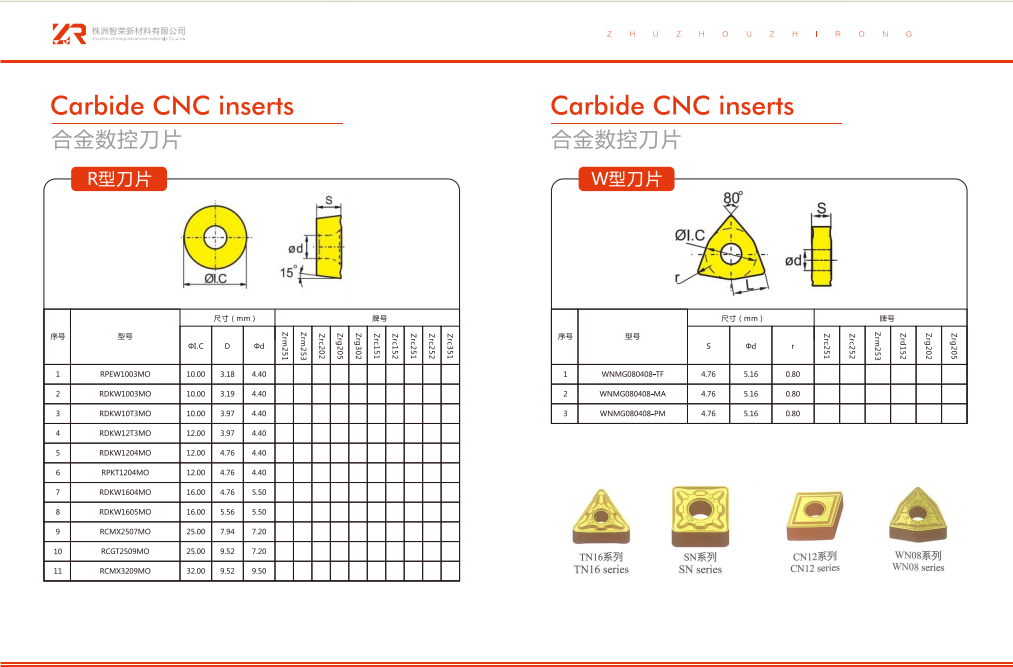

Zhuzhou Zhirong Indexable Carbide inserts

Carbide inserts are the backbone of modern metalworking.

They’re what give machinists a practical way to turn, mill, and drill most things. Carbide inserts are the go-to choice for most people in most applications. In this guide, I’ll explain why carbide inserts are better than other choices like solid high-speed steel (HSS) tools or brazed carbide tool bits. I’ll also show you how to select the right insert for your application.

Why I Quit Using Brazed Carbide Tools

For decades, machinists used brazed carbide tool bits. They’d take a little piece of carbide, braze it to a shank of steel, and grind the cutting edge. Brazed bits worked well, but they had some problems. How good the bit worked depended on how good the machinist was at brazing and grinding. Every time the tool needed to be sharpened, you had to take it out of the machine and grind it. That meant downtime.

Why I Quit Using HSS Tools

HSS (high-speed steel) has been around even longer than brazed carbide tools. It’s cheap, easy to sharpen, and lots of hobbyists use it. However, in the industrial world, HSS has a cutting speed of about one-fourth that of carbide. That makes it inefficient. Most people use solid carbide tooling for everything because it makes them more productive, lasts longer, and is more predictable. This is true for end mills and drills, which are used a lot in manufacturing. HSS tools are cheaper, but they don’t last as long or perform as well as carbide. That’s why a lot of tool companies don’t even offer HSS tools anymore. They only sell carbide.

Carbide Inserts: The Best Of Both Worlds

Carbide inserts are the workhorse of metalworking. We still use carbide, but instead of a permanent attachment, we have a little piece of carbide that gets clamped or screwed into the tool body. When the cutting edge wears down, you replace the insert. You don’t have to take the whole tool out of the machine to re-grind it or re-calibrate it. You just pop the insert out, put a new one in, and keep going. It saves you a lot of time and keeps your machine running. It’s that simple.

Carbide Inserts Are Versatile

One of the biggest benefits of using indexable carbide inserts is the number of different inserts available. Instead of having to grind a custom shape into your tool, you can buy an insert off the shelf for almost any application. You need to cut a fine groove? No problem. You need to machine threads? No problem. You need to make an angled cut? No problem. There’s an insert for everything. You don’t have to grind your own. You don’t have to figure it out. You don’t have to worry about it. You just buy the right one, put it in, and go. It’s easy.

Carbide Inserts Are Great For CNC

Carbide inserts are amazing for CNC (computer numerical control) operations. When you’re running a CNC machine, you don’t want to have a lot of downtime. You want to keep the machine running. You want to keep it cutting chips. You want to keep it making parts. You don’t want to be touching off tools, re-calibrating things, or grinding tools. You want to keep the machine running, and carbide inserts let you do that.

How To Pick The Right Carbide Insert

With all the different carbide inserts available, how do you pick the right one? Why are there so many different carbide grades, coatings, and geometries? The reason is because we can customize carbide inserts for specific materials. Shops that machine tough alloys like Inconel or Hastelloy can get inserts that are specifically designed for high-temperature performance. Shops machining stainless steel or titanium can get inserts that offer the best wear resistance for those materials. The automotive, aerospace, and medical industries all use material-specific carbide grades. They fine-tune their machining processes to get the best efficiency. If you’re machining cast iron, low carbon steel, or materials that are corrosion resistant, there’s a carbide insert that will help you get the best results.

General Purpose Carbide Inserts

Not every shop can afford to stock 30 different grades of carbide inserts. They can’t do it. For job shops that work with a lot of different materials, but not big quantities of each, general-purpose carbide inserts are a great solution. They’re not optimized for a specific material, but they work well in a lot of different metals. You can machine a range of metals without having an extensive tool inventory. You need to find a balance between having enough specialized inserts for the jobs you do every day and having general-purpose tools for the occasional job. That’s what job shops do.

How To Decode Carbide Insert Nomenclature

Most manufacturers use ANSI or ISO standards for naming carbide inserts. They use alphanumeric codes to indicate the shape (round, square, triangular), clearance angle, tolerance, size, corner radius, and other specifications. These codes can get pretty complex, but they’re a standardized way to identify the insert you need. Thankfully, most of the tool manufacturers have online tools and catalogs. They ask you questions about the type of machining you’re doing, the material you’re cutting, and how deep you’re cutting. Then, they recommend the specific carbide inserts and toolholders you need. They even give you the speed and feed recommendations to get the best productivity.

Conclusion: Carbide Inserts Win

Picking the right carbide insert can be overwhelming. However, with the online tools available today and the wide variety of material-specific and general-purpose options, it’s actually easier than ever. Whether you’re cutting aerospace alloys or basic steel components, carbide inserts give you the performance, durability, and ease of use that professional machine shops demand. They keep your machines running. They keep your downtime to a minimum. They help you get more done. Ultimately, carbide inserts help you make more money. So, when you’re trying to decide between HSS, brazed carbide, or carbide inserts, remember that carbide inserts are your best choice for high-performance metalworking.