Struggling to pick the right carbide insert from endless options? Choosing incorrectly wastes time, money, and ruins workpiece quality. Let me help you simplify the selection process for optimal results.

The best way to choose a carbide insert is by carefully considering the workpiece material, the specific machining operation (like turning, milling, roughing, finishing), machine conditions, and your desired tool life. Match the insert geometry, grade, chipbreaker, and coating to your application needs.

Making the right choice is crucial for efficiency and part quality. It might seem complicated with all the codes and options, but breaking it down makes it much easier. Follow along as we explore the key factors step-by-step, helping you select the perfect insert every time and avoid those costly mistakes. Let's get started.

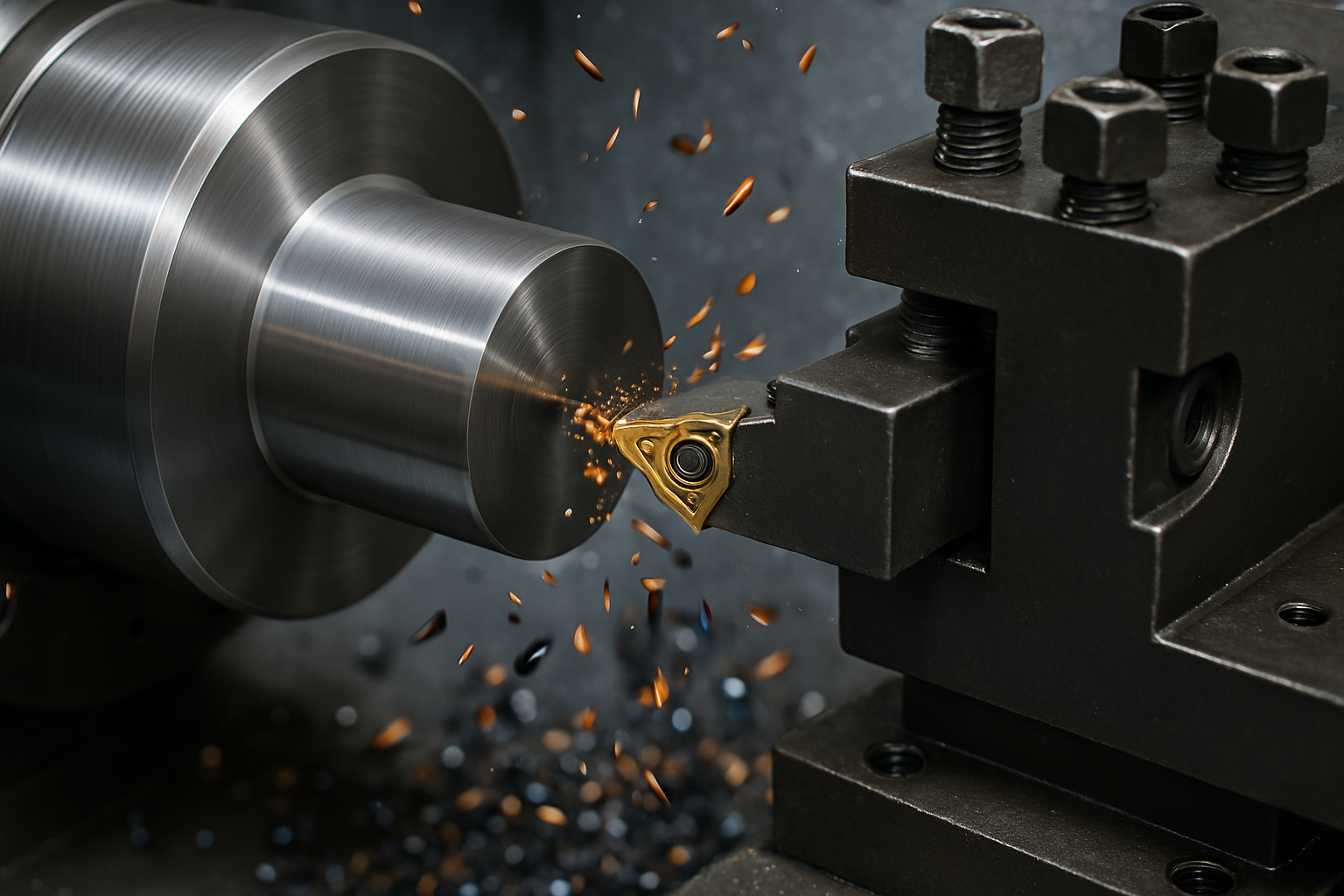

How to choose the correct turning insert?

Turning requires high precision, but the wrong insert can lead to poor finishes or scrapped parts. Don't guess! Select your turning insert based on key factors for success.

Choose turning inserts by matching the geometry (shape, clearance angle, nose radius), carbide grade (hardness/toughness), chipbreaker design, and coating to the specific material being turned and whether it's a roughing, semi-finishing, or finishing operation.

Choosing the right turning insert involves several important details. Think about the job you need to do. Are you taking off a lot of material quickly (roughing), or are you aiming for a smooth, precise surface (finishing)? This decision guides your choice.

Key Factors for Turning Inserts

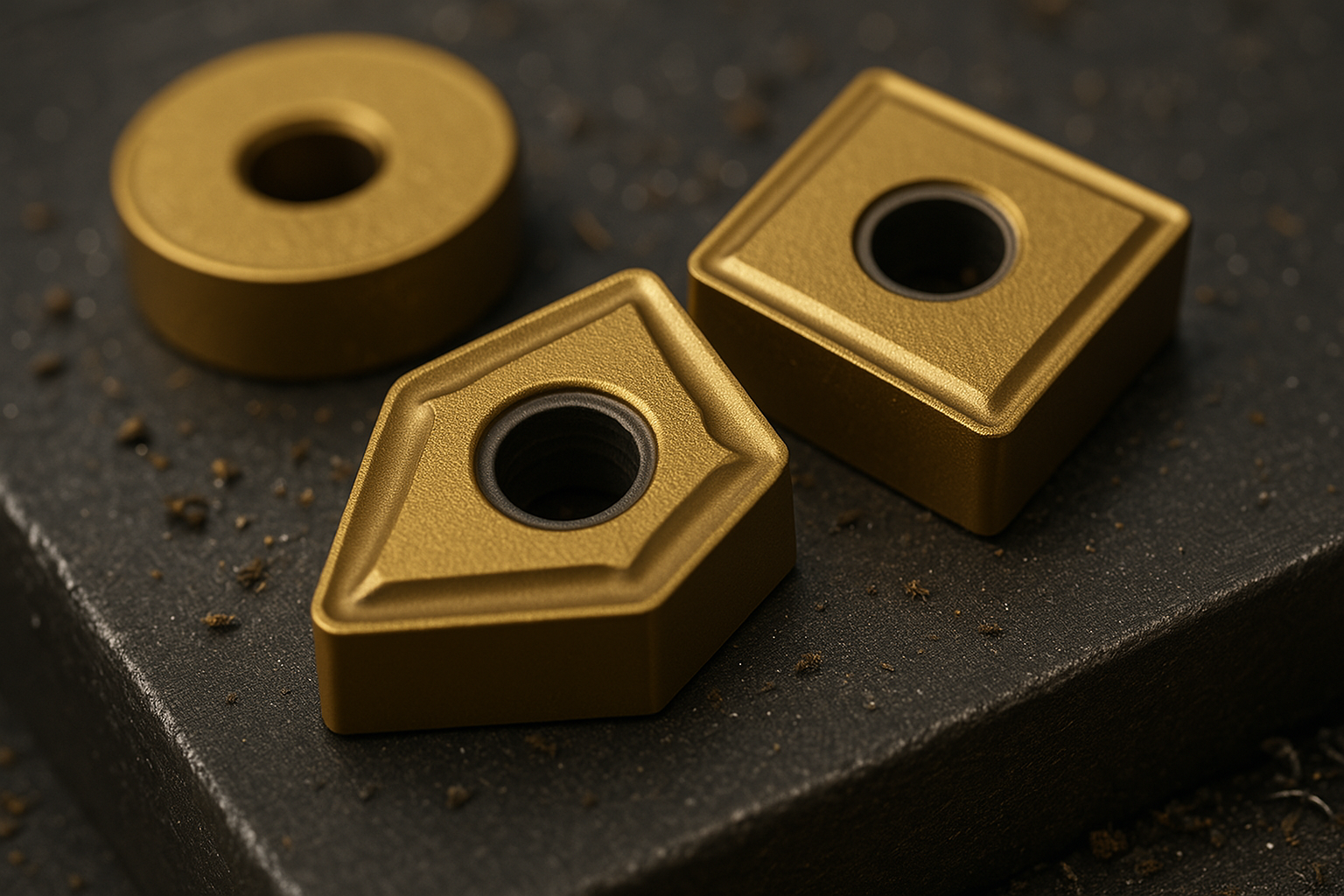

- Insert Shape: The shape affects strength and accessibility. Common shapes like C (80° diamond) and D (55° diamond) offer good strength for roughing, while V (35° diamond) allows for more intricate profiling but is less strong. T (triangle) is versatile. We offer shapes like TCMT and DNMG suited for various turning needs.

- Nose Radius (RE): This impacts surface finish and insert strength. A larger radius is stronger and allows higher feeds but can increase vibration risk. A smaller radius gives a better finish on fine cuts but is weaker.

- Grade Selection: Match the grade to the material (steel, stainless steel, cast iron, etc.). Harder grades offer [wear resistance](https://www.uplandfab.com/blog/the-best-wear-resistant-plastics-for-cnc-machining) for finishing, while tougher grades resist chipping in interrupted cuts or roughing. Our grades use 100% virgin carbide powder for excellent wear resistance and toughness.

- Chipbreaker: This geometry on the insert face controls [chip formation](https://www.smartlathe.com/blogs-1/the-impact-of-spindle-speed-and-feed-rate-on-chip-formation), crucial for preventing damage and ensuring smooth operation. Different chipbreakers work best for different materials and depths of cut.

Here’s a simple comparison:

| Feature | Rough Turning | Finish Turning |

|---|---|---|

| Goal | High material removal rate | High surface finish, tight tolerance |

| Insert Shape | Strong shapes (C, S, R) | Shapes allowing access (D, V, T) |

| Nose Radius | Larger (e.g., 0.8mm, 1.2mm) | Smaller (e.g., 0.2mm, 0.4mm) |

| Grade | Tougher grade | Harder, wear-resistant grade |

| Depth of Cut | Deep | Shallow |

| Feed Rate | High | Low |

At Zhirong, our [turning inserts](https://www.sandvik.coromant.com/en-us/knowledge/general-turning/how-to-choose-correct-turning-insert) are designed to increase production and improve part quality. We can help you select the ideal combination for your specific turning application, whether OD turning, ID turning, profiling, or grooving.

Which insert type is the best choice for rough machining?

Rough machining puts extreme stress on inserts. Using an insert meant for finishing will cause it to break or wear out instantly. You need something built tough for heavy cuts.

For rough machining, choose inserts with strong shapes (like round, square, or 80° diamond - CNMG, SNMG, RNMG), negative rake angles for edge strength, a tough carbide grade, and a thick, durable coating (like CVD) suitable for high temperatures.

Roughing is all about removing large amounts of material quickly and reliably. Finishing focuses on precision and surface quality, but roughing demands strength and durability above all else. The insert needs to withstand heavy cutting forces, high temperatures, and potential interruptions without failing.

Characteristics of Good Roughing Inserts

- Strong Geometry: Shapes like Round (R), Square (S), or Trigon (W), and robust rhombic shapes like C (80°) provide maximum edge strength compared to sharper V (35°) or D (55°) shapes used for finishing. Negative rake inserts add further edge strength, using compression rather than shearing action.

- Tough Carbide Grade: While hardness resists abrasive wear, toughness prevents chipping and breakage under heavy loads and interrupted cuts common in roughing. You need a grade specifically designed for toughness, even if it means slightly faster wear in ideal conditions. Our engineers often recommend specific tough grades for materials like stainless steel or high-temp alloys common in automotive or aerospace roughing.

- Reliable Chip Control: Roughing produces large, hot chips. A suitable chipbreaker geometry is essential to break these chips effectively, preventing them from damaging the tool or workpiece and ensuring operator safety. Chip control needs to be effective across a wide range of high feeds and depths of cut.

- Appropriate Coating: A thick Chemical Vapor Deposition (CVD) coating is often preferred for roughing steel and cast iron. It provides excellent thermal insulation and crater wear resistance at high temperatures generated during heavy cuts. PVD coatings might be better for stainless steels or non-ferrous materials due to their sharper edge retention.

Here’s a comparison:

| Feature | Roughing Insert | Finishing Insert |

|---|---|---|

| Shape | Strong (R, S, C, W) | Accessible (V, D, T) |

| Rake Angle | Often Negative | Often Positive |

| Grade | High Toughness | High Hardness |

| Coating | Thick (e.g., CVD) | Thin, smooth (e.g., PVD) |

| Edge Prep | Stronger (e.g., honed) | Sharper |

We understand the demands of rough machining across various industries. Zhirong provides robust inserts designed for high material removal rates, ensuring reliability even in demanding applications.

How do I choose my insert grade?

Seeing all the different grade codes can be overwhelming. Pick the wrong one, and your insert might wear instantly or shatter unexpectedly. Understanding grades is key to performance.

Choose your insert grade primarily based on the material you are machining (using the ISO P-M-K-N-S-H system) and the type of operation (roughing vs. finishing). Balance the need for hardness (wear resistance) against toughness (chipping resistance).

The carbide grade is basically the specific recipe of the carbide material itself. It dictates the fundamental properties of the insert before any coating is applied. Getting this right is fundamental to tool life and performance. The industry uses a standard system to help simplify this.

Understanding ISO Material Groups and Grade Properties

The ISO system classifies workpiece materials into six main groups, each represented by a letter and color code:

- P (Blue): Steels (the largest group)

- M (Yellow): Stainless Steels

- K (Red): Cast Irons

- N (Green): Non-ferrous Metals (Aluminum, Copper, Brass)

- S (Orange): Heat-Resistant Super Alloys (HRSA) and Titanium

- H (Gray): Hardened Materials

Carbide grades are designed with properties optimized for one or more of these groups. Within each group, grades vary on a scale of hardness versus toughness:

- Hardness: Resists abrasive wear, flank wear, and deformation at high temperatures. Ideal for finishing operations requiring long tool life and good surface finish.

- Toughness: Resists chipping, breakage, and thermal shocks. Critical for roughing operations, interrupted cuts, or unstable machining conditions.

Generally, there's a trade-off: increasing hardness decreases toughness, and vice versa.

The Role of Coating

Here's where my experience tells me coating plays a huge role. A good coating, whether PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition), significantly enhances performance. It acts as a thermal barrier, reduces friction, and increases surface hardness. Sometimes, a well-chosen coating can compensate for a slightly less-than-ideal substrate grade, extending tool life dramatically. We offer both PVD and CVD options tailored for different applications based on decades of R&D and feedback.

| ISO Code | Material Group | Typical Grade Focus | Zhirong Application Examples |

|---|---|---|---|

| P | Steel | Balanced / Wear | Automotive components, general machining |

| M | Stainless Steel | Toughness / Sharp Edge | Food processing, chemical equipment |

| K | Cast Iron | High Wear Resistance | Engine blocks, pump housings |

| N | Non-ferrous (Al, Cu) | Sharp Edge / Anti-Stick | Electronics, aerospace components |

| S | Superalloys (Inconel), Ti | Toughness / Heat Res. | Aerospace engines, power generation |

| H | Hardened Steel (>45 HRC) | High Hardness / Heat | Mold & die manufacturing |

As Zhirong's Sales Manager, I often help customers navigate this. Simply tell us the material and operation, and we can recommend the best grade and coating combination from our extensive range, drawing on our 15+ years of experience and advanced R&D. We even offer free samples so you can test performance yourself.

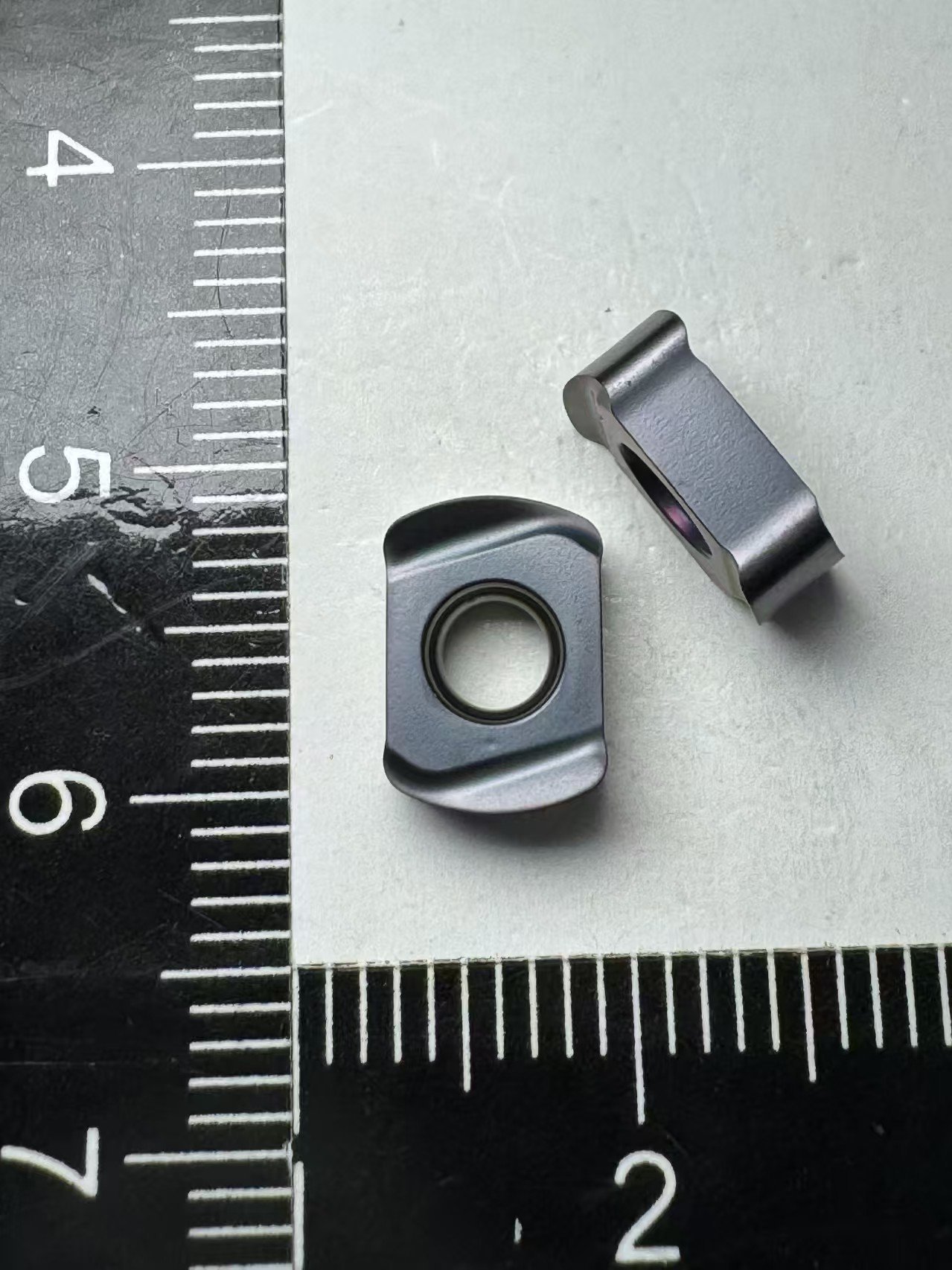

How do I choose the right insert size?

Does the physical size of the insert matter much? Absolutely! Choosing a size that's too small leads to breakage, while too large might not fit or be overkill. Match the size to the job.

Select insert size based on the required maximum depth of cut (DOC) and the specifications of your toolholder. Larger inserts generally handle deeper cuts and higher feed rates but need more machine power and stable conditions.

The size of the insert directly relates to its strength and how much material it can remove in a single pass. It's usually indicated in the ISO designation code for the insert. Getting the size right ensures the insert fits correctly in the holder and can withstand the cutting forces involved.

Factors Determining Insert Size

- Depth of Cut (DOC): This is the primary factor. A larger depth of cut requires a longer cutting edge and a more robust insert body to handle the increased forces. As a rule of thumb, the cutting edge length (L) should generally be greater than the depth of cut.

- Toolholder Compatibility: The insert must fit perfectly into the pocket of the toolholder being used. The ISO code contains information about the shape and size (often the Inscribed Circle diameter - IC for round, square, trigonal inserts, or the edge length L for rhombic/rectangular ones) that must match the holder's specifications. Using the wrong size can lead to poor seating, vibration, and tool failure. Common sizes we stock include those for popular designations like TCMT160404 or DNMG150608, where the bolded numbers indicate size.

- Machine Power and Stability: Larger inserts engaging in heavier cuts require more spindle power and torque from the machine tool. They also demand a rigid setup (machine, toolholder, workpiece clamping) to avoid vibration, which can lead to poor surface finish or insert breakage.

Reading Size from ISO Code

The size is typically indicated by a number in the ISO designation. For example:

- CNMG 12 04 08: The '12' often indicates the length of the cutting edge (L) in mm (12mm). The IC would be derived from this and the shape.

- TCMT 16 T3 04: The '16' often indicates the length L (16.5mm for TCMT). The 'T3' can refer to thickness (3.97mm).

Here's a general guide:

| Feature | Smaller Insert Size (e.g., IC 9.525mm / L 11mm) | Larger Insert Size (e.g., IC 15.875mm / L 16mm) |

|---|---|---|

| Max DOC | Smaller | Larger |

| Strength | Lower | Higher |

| Machine Power | Lower requirement | Higher requirement |

| Application | Finishing, light-medium cuts | Roughing, heavy cuts |

| Example Code | TCMT110204 | CNMG160612 |

At Zhirong, we offer a wide range of standard insert sizes, including popular ones like TCMT160404 and DNMG120408. If you're unsure, just provide details about your operation (especially the depth of cut) and toolholder, and we can help you select the most appropriate and cost-effective size.

Conclusion

Choosing the right carbide insert involves matching the material, operation, grade, geometry, coating, and size. Get these right, and you'll boost productivity and quality. Contact us at Zhirong for expert advice!